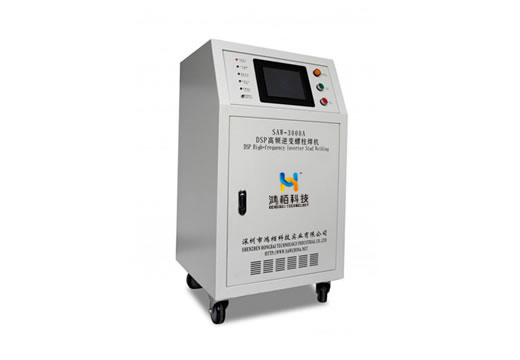

SAW-3000A型螺柱焊机

- 在售状态:已停产

该成套设备主机采用IGBT逆变节能技术和DSP全数字控制技术,自带5个焊枪 接口,可实现手动装钉、人工焊接;自动装钉、人工焊接和与机器人 连接的全自动焊接。

该设备的最大焊接电流可达1500A。

The welding system applies IGBT inverter technolog and DSP control technology, and have the capacity carrying 5 welding can be achieved,when the system docks with robots under auto-feeding.

Max. welding current can reach 1500A.

主机主要技术性能 TECHNICAL DATA

A、电路拓扑:全桥全波整流

B、电流控制技术:恒流PWM

C、功率开关:IGBT

D、功率变压器:铁氧体

E、监控接口:光电隔离

F、系统控制:DSP数字处理器

G、操作控制:触摸屏

H、屏幕显示:中/英文

I、网络拓扑:RS 485实时半双以太网及CAN总线

J、硬件抗干扰:隔离供电,信号光电隔离

K、软件抗干扰:分布式WatchDog跑飞复位。回传校验,

在线空闲自检,主动休眠回避

L、监测系统:实时工况及故障监测

M、质量保证:焊接质量监测及优化

A. Circuit topology: Full Wave Bridge Rectification

B. Current control technology: PWM

C. Power switch: IGBT

D. Power transformer: ferrite

E. Interface monitoring: optoelectronic isolation

F. System Control: Microprocessor

G. User interface: Touch screen

H. Language: Chinese/English

I. Network topology: Real-time half-DUPLEX RS 工 , 485

J. Hardware Anti-interference: isolated power supply

K. Software Anti-interference: Distributed Watchdog,

error return and check, hiccup reset

L. Monitoring system: real-time working condition and fault detection

M.Quality assurance: monitoring and optimization of welding quality

- 主机型号:SAW-3600A

- 工作方式:手动/半自动

- 支持螺柱材质:钢制螺柱

- 通信总线:DeviceNet、profinet、profibus、CC-Link、EtherNet/IP等

- 伺服驱动器:集成

- 输入电源:AC 3*380±15% 50~60Hz

- 输出功率:90KVA

- 空载电压:V

- 焊接电流范围:In:100~1500A

- 焊接电流控制精度误差:%

- 焊接时间调节范围:6~100ms

- 焊接螺柱直径:Φ:3~10mm

- 额定占载率:%

- 主机重量:80kg

- 主机体积:550mm*500mm*1000mm